What is a solar connector?

A solar panel PV connector serves as a vital link between solar panels and the electrical grid or other devices, enabling the efficient utilization of solar energy.Solar connectors not only directly affect the power generation efficiency of the system, but also the safety and stability of the entire photovoltaic system. This article will analyze the core value of this "green energy bridge" from the perspectives of functional characteristics, application scenarios and classification.

1. Core functions and features of solar connectors

High-efficiency conductivity and low-loss transmission

Solar connectors are designed with high-purity copper alloy or silver-plated contacts to ensure that the current transmission efficiency reaches more than 99%. For example, the contact resistance of the industry standard MC4 connector is less than 0.5mΩ, which can effectively reduce the energy loss caused by resistance heating and improve the overall power generation efficiency of the photovoltaic system.

Weather resistance and long life

Facing harsh environments such as high temperature, ultraviolet rays, and rain erosion outdoors, solar connectors must have an IP68 waterproof rating (such as the H4 series) and a temperature resistance range (-40℃~90℃). Its outer shell is mostly made of UV-resistant engineering plastics, and the internal sealing ring is made of silicone material to ensure a service life of more than 25 years.

Safety protection mechanism

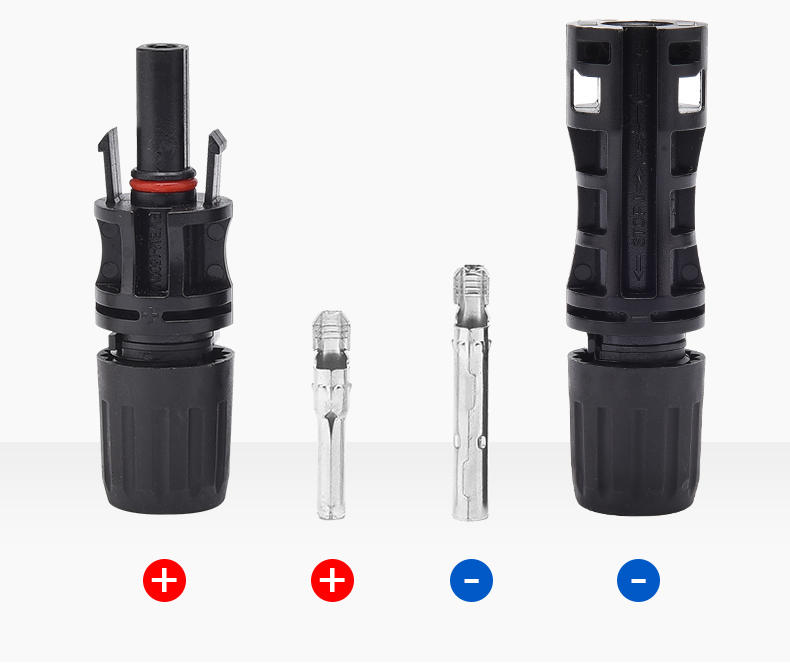

Through anti-reverse plug-in design (such as the special-shaped structure of male and female heads), anti-electric shock buckle locking (such as the "click" sound prompt of MC4) and fire-retardant materials (UL94 V-0 certification), it effectively avoids installation errors, accidental detachment or short circuit risks.

Fast installation and compatibility

Mainstream connectors support "plug and play" tool-free installation and are compatible with PV modules and inverters of different brands. For example, the MC4 connector is certified by the international IEC 62852 standard and has become a universal interface for the global PV market.

2. Main categories of solar connectors

Based on structure, purpose and current carrying capacity, solar connectors can be divided into the following types:

Classification by structural type

MC series: such as MC3, MC4 (Most Common 4mm, 4mm diameter contacts), of which MC4 occupies 80% of the market share due to high compatibility.

H4 series: an upgraded version suitable for high-power components, supporting higher currents (such as 40A).

Direct plug-in and rotary type: the latter improves waterproofness by screwing, and is often used in offshore photovoltaic or high humidity scenarios.

Classification by application scenario

Board-end connector: directly integrated into the backplane of the photovoltaic component, used for series connection of components.

Line-end connector: installed at the end of the cable, connected to the inverter or junction box.

Branch connector: realize multi-way parallel connection, such as T-type branch head.

Classification by current level

Low voltage and low current type: suitable for household systems (such as 20A/1000V).

High voltage and high current type: used for industrial and commercial power stations (such as 30A/1500V).

3. Analysis of typical application scenarios

Household photovoltaic system

In a household rooftop power station, the connector connects 6-12 modules in series to form a string, and then connects to the inverter. It is necessary to use a lightweight and easy-to-install MC4 connector, and use an intelligent monitoring plug to detect the connection status in real time.

Large ground power station

Hundred-megawatt power stations require tens of thousands of pairs of connectors, and enhanced products that are resistant to high temperatures and dust are often used.

Off-grid energy storage system

In the photovoltaic + energy storage scenario, the connector needs to adapt to both the module end (DC 1000V) and the battery end (DC 48V). Some models support DC fast plug-in, such as jixiang's dedicated energy storage interface.

New energy vehicle charging pile

In vehicle-mounted photovoltaic sunshades or mobile charging stations, the connector must meet the requirements of vibration resistance and plug-in resistance (>1000 times)

4. Why choose Jixiang's solar connectors

Efficiency: Minimize energy loss with low-resistance connections.

Sustainability: Enable renewable energy adoption by ensuring reliable system operation.

Cost Savings: Durable designs reduce maintenance and replacement costs over time.

Conclusion

As the "invisible guardian" of the photovoltaic system, solar connectors balance efficiency and safety with precise design, promoting the reliable implementation of green energy. From rooftops to deserts, from components to power grids, this inconspicuous small component is continuously empowering global energy transformation with technological innovation.